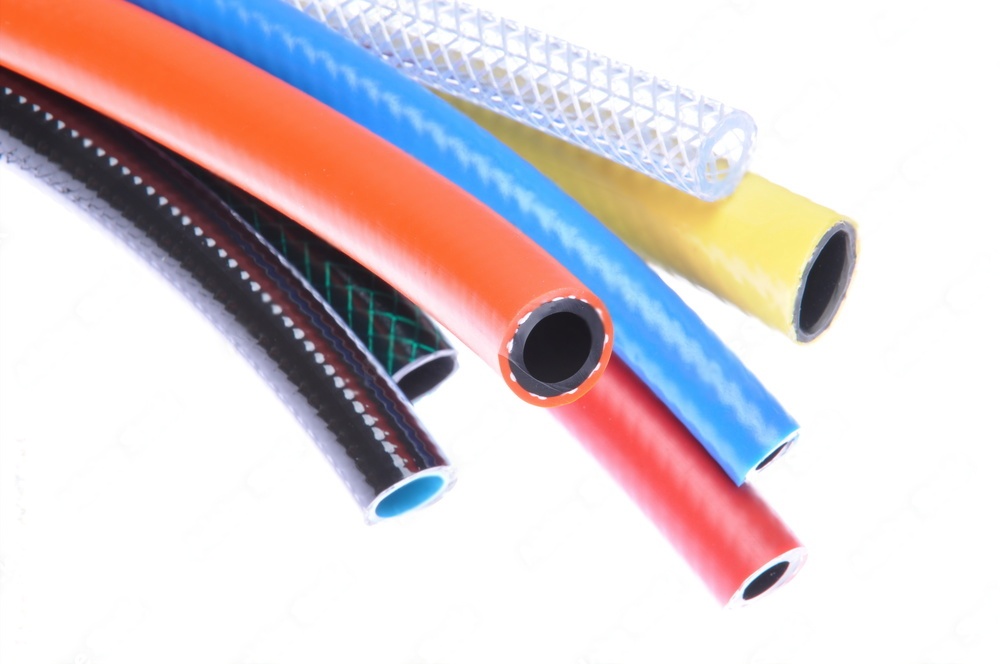

Hydraulic Pipes and Hoses

Hydraulic hoses are vital components in hydraulic systems, facilitating the transfer of pressurized hydraulic fluid to power various machinery and equipment. At Humbtech solutions, we offer a comprehensive range of hydraulic hoses designed to meet the diverse needs of our customers.

Rubber Hydraulic Hoses

Rubber hydraulic hoses are the most common type, known for their flexibility, durability, and resistance to abrasion and corrosion. They are suitable for a wide range of applications and operating conditions.

Steel Wire Braided Hydraulic Hoses

Steel wire braided hydraulic hoses feature a reinforced construction with multiple layers of high-tensile steel wire braid, providing enhanced strength and flexibility. They are suitable for applications requiring high-pressure performance.

Steel Wire Spiral Hydraulic Hoses

Steel wire spiral hydraulic hoses are designed for extreme high-pressure applications, featuring a spiral reinforcement of four or six layers of high-tensile steel wire. They offer superior resistance to pressure pulsation, vibration, and external forces.

Thermoplastic Hydraulic Hoses

Thermoplastic hydraulic hoses are lightweight and flexible, making them ideal for applications where weight savings and tight bend radii are critical. They offer excellent chemical resistance and are often used in high-pressure hydraulic systems.

Textile Braided Hydraulic Hoses

Textile braided hydraulic hoses feature a single or multiple layers of textile reinforcement, providing flexibility and moderate pressure capabilities. They are commonly used in low to medium-pressure hydraulic systems.

FAQ

What are hydraulic pipes and hoses used for?

Hydraulic pipes and hoses are essential components in hydraulic systems, used to transmit fluid power within machinery and equipment. They enable the movement of hydraulic fluid to operate various components such as cylinders, motors, and valves.

Can hydraulic pipes and hoses be customized for specific applications?

Yes, many suppliers offer custom hydraulic solutions tailored to meet the specific requirements of different applications. This may involve custom fabrication of pipes or hoses to precise specifications, as well as providing specialized fittings, adapters, or assemblies to suit unique system designs or operating conditions.

Can hydraulic pipes and hoses be repaired or replaced?

In many cases, hydraulic hoses can be repaired using couplings or fittings to address minor damage or leaks. However, extensive damage or wear may require replacement of the hose or pipe. It’s important to use compatible replacement parts and follow manufacturer recommendations for installation and maintenance.

How can I troubleshoot hydraulic pipe or hose issues?

Troubleshooting hydraulic pipe or hose issues involves identifying the root cause of problems such as leaks, pressure loss, or system malfunctions. This may require inspecting components for damage, checking connections for tightness, verifying fluid levels and pressures, and consulting system documentation or technical resources for guidance. If in doubt, it’s recommended to seek assistance from a qualified hydraulic technician or specialist.

What materials are hydraulic pipes and hoses made from?

Hydraulic pipes are commonly made from materials such as steel, stainless steel, or reinforced rubber, chosen for their durability, flexibility, and resistance to high pressure and corrosion. Hoses are typically constructed from rubber or thermoplastic materials, reinforced with layers of synthetic fibers or steel wire.

What maintenance is required for hydraulic pipes and hoses?

Regular inspection and maintenance of hydraulic pipes and hoses are crucial for ensuring system reliability and safety. This includes checking for signs of wear, damage, leaks, and proper routing and securing of hoses. Replacing worn or damaged components promptly can prevent costly failures and downtime.

How do I select the right hydraulic pipe or hose for my application?

Choosing the appropriate hydraulic pipe or hose involves considering factors such as operating pressure, temperature, fluid compatibility, size, and bend radius requirements. Consulting with a hydraulic specialist or referring to technical specifications provided by manufacturers can help ensure you select the right component for your specific application.

Are there regulations or standards for hydraulic pipes and hoses?

Various international standards and regulations govern the design, manufacture, and use of hydraulic pipes and hoses to ensure safety and performance. These may include standards from organizations such as ISO (International Organization for Standardization) and SAE (Society of Automotive Engineers), as well as industry-specific regulations and guidelines.

"Unlock Efficiency: Transform Your Hydraulic System with Humbtech Premium Pipes!"

“Seize the Power: Elevate Your Hydraulic Operations Today – Contact Us for Expert Solutions!”